What is (SPF) Spray Foam Roofing?

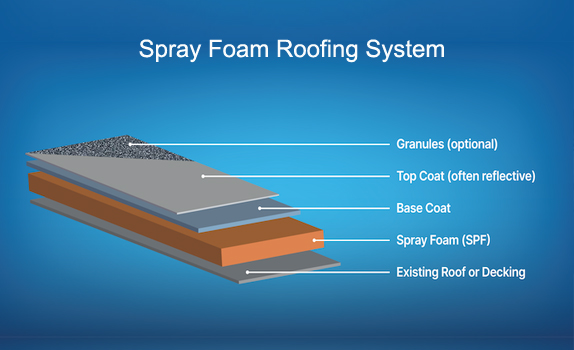

Spray foam roofing is a watertight roofing system that has three parts:

- Spray polyurethane foam (SPF) is sprayed over existing roof or decking.

- Silicone coating is installed in two coats: A base coat and a top coat.

- Granules which can be optional.

The polyurethane foam is produced by combining and heating two chemicals. These chemicals are pumped from a truck, transferred through a heated hose, and then sprayed onto an existing roof. The foam increases in thickness by 30x, reaching an average height of around 1.5 inches. The spray foam’s height (or thickness) is customized to every roofing system to create a slope for water to run toward drains.

Spray foam gets damaged from UV rays, so a thin layer of silicone coating is installed over the foam to protect it. The thickness of the silicone coating is usually around 20 – 30 mils. The silicone coating is installed in two separate coats, where the topcoat can be embedded with granules. Granules are suggested for added strength, durability, UV resistance and also to create traction for safe walking. Granules can also be used to create a decorative finish

What we do

Step 1: Preparation and Cleaning

We thoroughly clean the roof surface to remove dirt, debris, and any existing coatings.

We then repair any damage to the roof structure, such as leaks or cracks.

Step 5: Top Acrylic Coat

Benefits of SPF

Energy Efficiency: Reduces energy consumption by providing excellent insulation, leading to lower heating and cooling costs.