What is TPO roofing?

Thermoplastic Polyolefin (TPO) roofing is a single-ply roofing membrane that’s used for low-slope and flat roofs on commercial and residential buildings.

- TPO is made of a combination of polypropylene and ethylene-propylene rubber. It’s typically white and has a shiny, reflective appearance.

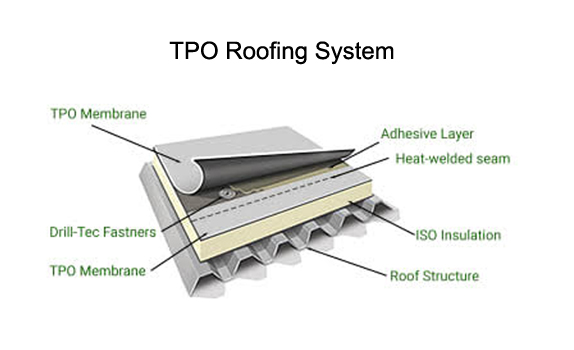

- TPO is attached to the roof with adhesives, mechanical fasteners and heat welding.

TPO is the short name for thermoplastic polyolefin. This innovative material is made up of polypropylene, a chemical compound known for its elasticity and durability and commonly used in the manufacturing of a slew of both industrial and household products. Polypropylene is also known for its slippery characteristic, which means it can work well to repel moisture from potential roof wreckers like rain or snow.

The other important component of TPO is ethylene-propylene rubber, a synthetic elastomer related to rubber. TPO material is typically manufactured in sheets that are available in various sizes, and is distinguished by its bright white color. Because of this substance’s ability to resist weather, ozone rays, heat and oxidation, it is an ideal ingredient for this type of application.

What we do

Step 1: Preparation and Cleaning

Roof Inspection: Thoroughly inspect the existing roof for damage, leaks, or unevenness.

Removal: If necessary, remove the old roofing material and clean the roof surface.

Repair: Address any underlying structural issues or damage to the roof deck.

Step 4: TPO Membrane Installation

Step 5: Flashing and Accessories

Flashing Installation: Install flashing around penetrations, such as pipes, vents, and skylights, to prevent leaks.

Step 6: Quality Control and Inspection