What is Silicone Roofing?

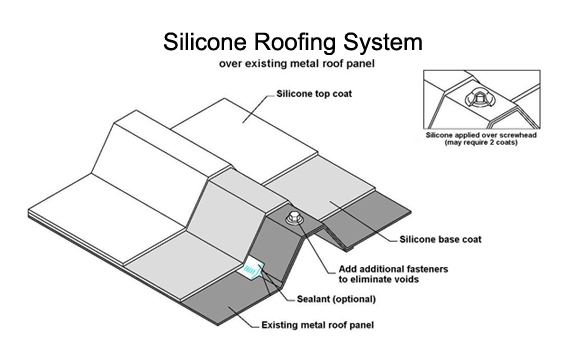

Silicone roofing is a protective coating applied to a roof to fill in cracks, blisters, and seams, and to shield the roof from the elements.

- Silicone roof coatings create a highly flexible, monolithic, and impermeable membrane capable of withstanding wind-driven sand, oxidation, and extreme temperatures. They are also able to endure the natural expansion and contraction (thermal movement) that occurs in large roof structures.

Silicone roof coatings are perhaps the most popular chemistry type in the roof restoration industry—and for good reason! They make a great solution to restore and protect a wide variety of commercial roofing substrates including metal, modified bitumen, single-ply, EPDM, TPO, built-up roofs, concrete roof decks, and spray polyurethane foam.

What we do

Step 1: Initial Assessment and Preparation:

Thorough inspection of the existing roof to identify any damage, leaks, or areas requiring repair.

Cleaning of the roof surface to remove dirt, debris, and any contaminants that may hinder adhesion.

Repair of any identified damage, such as cracks, punctures, or loose seams.

Priming of the roof surface to ensure proper adhesion of the silicone coating.

Ensuring even coverage and proper thickness of the coating across the entire roof surface.

Allow the first coat to cure completely according to the manufacturer’s specifications.

Optional: Application of a second coat of silicone coating to provide additional protection and durability (discuss with your roofing professional to determine if a second coat is necessary for your specific needs).

Inspection of the finished coating to ensure it meets quality standards and provides a seamless, watertight seal.