What is Modified Bitumen Roofing?

It is a flexible, waterproof, and durable roofing material made from asphalt, polymerized rubber or plastic, and fiberglass or polyester:

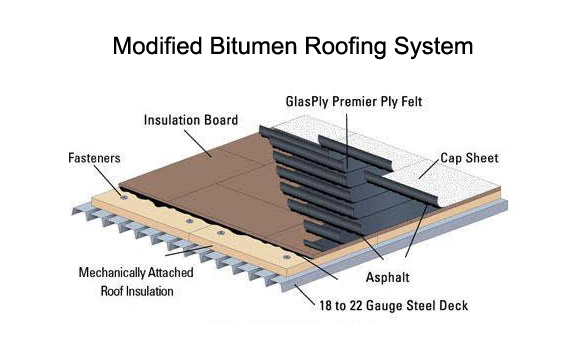

- Modified Bitumen is a hybrid material combines asphalt membranes with polymerized rubber or plastic and is reinforced with fiberglass, creating a sturdy yet flexible roofing material.

MB roofing or Torch down can be installed in various configurations, including two-layer and multi-ply systems. The type of facility, location, access, deck, insulation type, climate, and customer requirements are some of the reasons for the various installation methods.

Mod bit is common in commercial, industrial, and residential applications and ideal for use on flat and low-slope roofs. Depending on the material type, these systems generally consist of two or more layers (multi-ply).

What we do

Step 1: Preparation

Inspection and Assessment: Thoroughly examine the existing roof for any damage, leaks, or structural issues that need to be addressed before proceeding.

Removal of Old Roof (if applicable): If the existing roof is beyond repair or incompatible with modified bitumen, it needs to be carefully removed.

Step 4: Self-Adhered Modified Bitumen Layers (optional)

Step 5: Flashing and Detail Work

Install Flashing: Install flashing around roof penetrations, such as vents, pipes, and skylights, to prevent leaks. Use appropriate sealants and adhesives to ensure a watertight seal.

Step 6: Finishing Touches